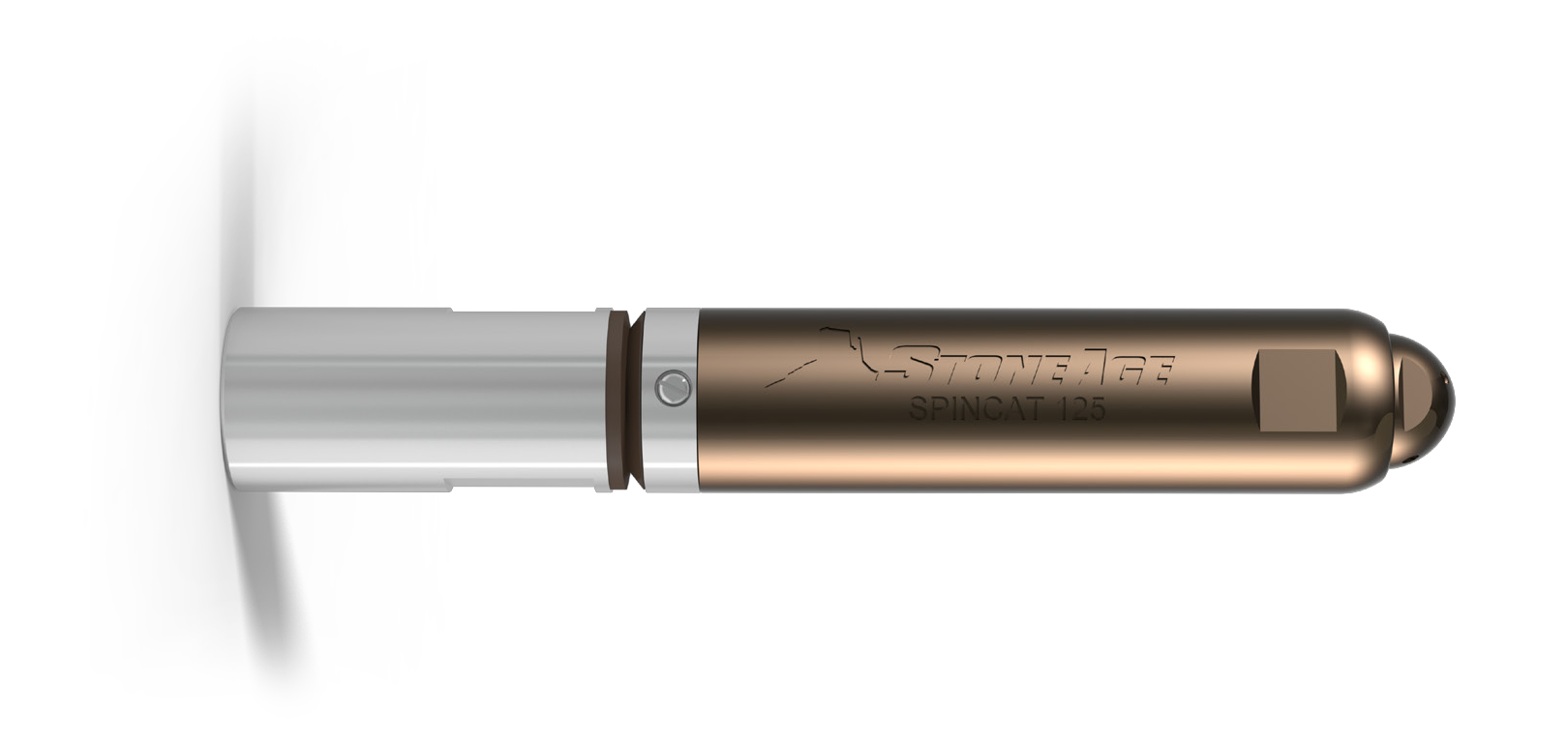

SpinCat self-rotating jetting tools are included in the Hydropulsion range of Wellbore Cleanup tools.

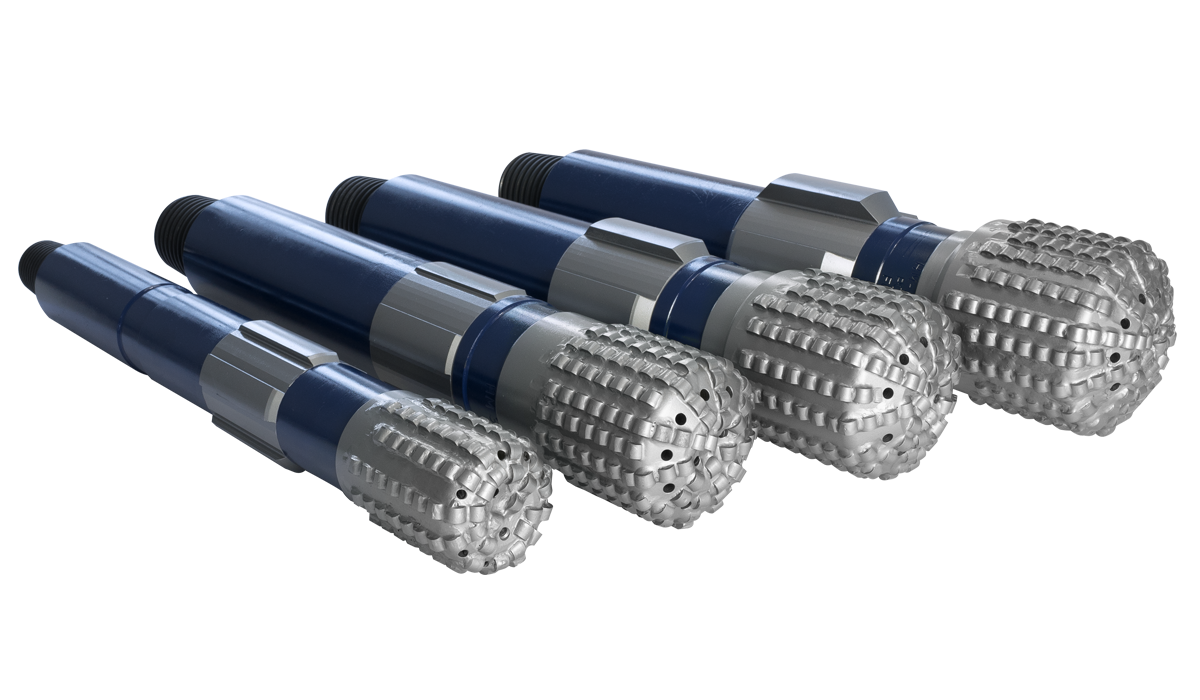

Hydropulsion Ltd has been the Factory authorised international dealer for over 18 years, supplying the SpinCat family of downhole rotating wash tools, spare parts, accessories & custom solutions to clients globally.

The SpinCat family of tools provides a durable, controlled rotation solution for well intervention operations.

Jet reaction force powers the rotation of the head and an internal centrifugal speed control mechanism maintains rotation speeds to maximize jet power delivered to the tubing walls. Using only a few rotating jets, each jet is bigger to convey hard-hitting power.

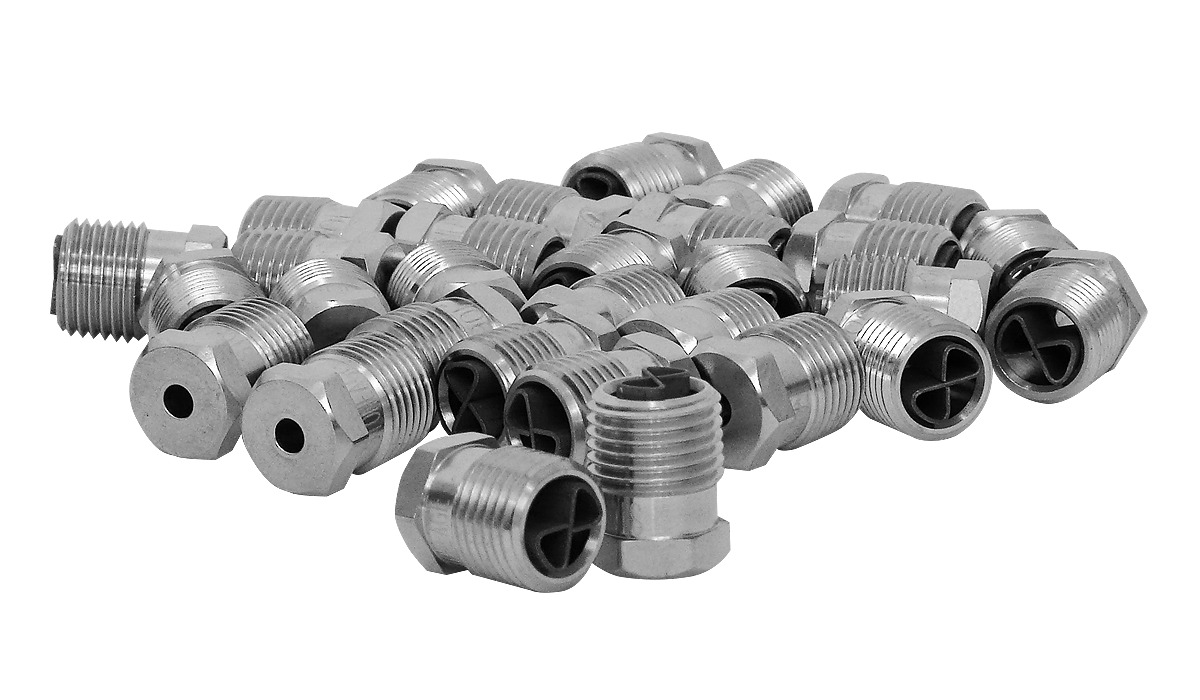

Replaceable jets are efficient and clean recesses and irregular surfaces without damaging the well pipe. Over forty years of waterjet engineering back the SpinCat design, setting the standard for rotary nozzle performance and durability.

SpinCat tools have a straight flow-through design with a leak-free high-pressure seal, so pump power is not wasted. The tools can be used at temperatures up to 200°C, with up to 30% HCL and Nitrogen injection.

As well as the standard Nozzle / Head configuration, the SpinCat can be customized to suit specific cleaning requirements.