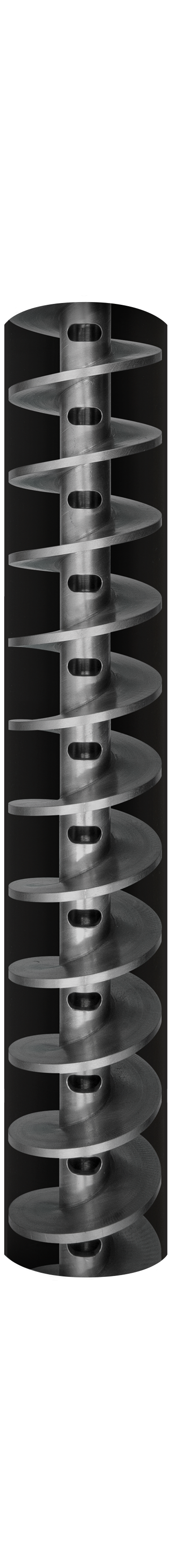

Downhole Gas Separator

GMASS ( Gas Management & Separation System ) is a downhole gas separator used to separate the gas from liquid when two phase fluids are used, enhancing equipment reliability and performance, particularly with PDM’s, by minimising the amount of gas that passes through the motor, which in turn maximises performance and minimises cost.

GMASS System

The GMASS Downhole Gas Separator was originally designed to be used in underbalanced operations (drilling milling and jetting). The downhole gas separator is placed above the Motor or Jetting Tool and separates the gas from liquid phases in a nitrified fluid.

This reduces the volume of gas passing through the BHA preventing damage to motors (drilling and milling) and increasing the impingement force of jets (jetting) while maintaining an underbalanced condition in the annulus.

The system is comprised of two (2) components, a Gas Management Module and a Gas Separation Module.

GMASS Advantages

- Enhance equipment reliability and performance, particularly with PDMs, by minimising the amount of gas that passes through the motor thus minimising damage to the stator and reducing downtime, which in turn maximises performance and minimises cost.

- Ensure faster drilling/milling operations by maximising fluid volumes that reach the motor increasing efficiency and power delivery.

- Remove the need to retrieve and change BHA configuration once gas is not required as GMASS can work with single fluids or multiphase fluids.

- GMASS available in 1 11/16″, 2 1/8″ & 2 7/8″ ODs

- The GMASS has no moving parts, reducing the risk of tool failure downhole.

Want to learn more about our GMASS System?

Download the pdf datasheet, or get in touch

via our contact page